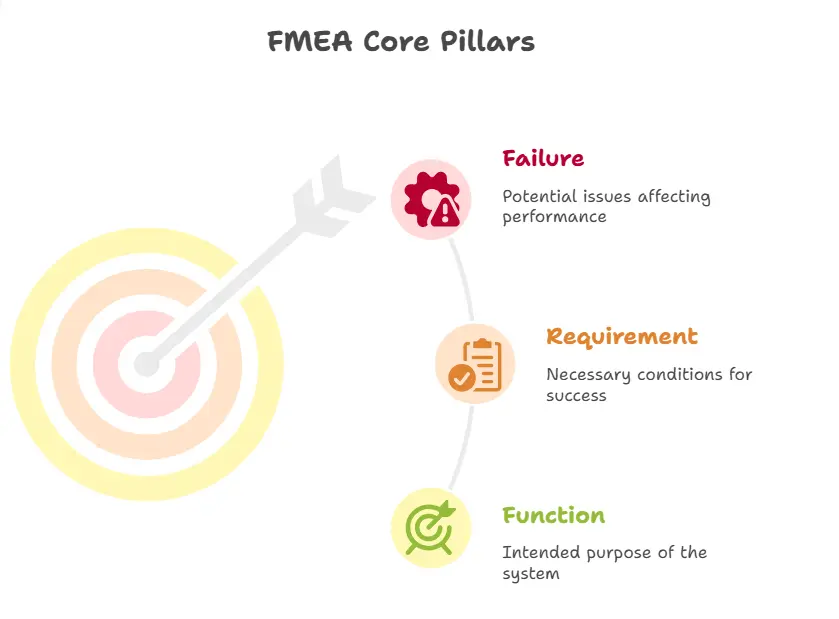

If you’re serious about performing an effective FMEA, you must master the three core pillars: Function Requirement Failure in FMEA

- Function

- Requirement

- Failure

These three elements are fundamentals of every DFMEA and PFMEA. They form the “backbone” and link your risk analysis to performance, customer satisfaction, and safety.

When you get these three right, the rest of your FMEA (Failure Mode and Effect Analysis) becomes meaningful. If you get them wrong, your entire analysis will be built on a weak foundation.

Let’s break them down with definitions, examples, and expert advice from the AIAG-VDA FMEA Handbook.

1. Function: What the Product or Process Is Intended to Do #

A Function describes what a part/component, system, or process is intended to do, either in terms of:

- Design (DFMEA): Functional behavior of the product

- Process (PFMEA): Purpose of the manufacturing or assembly step

In DFMEA:

“The [Design] Function defines what the item must perform or achieve under specified conditions.”

Examples of DFMEA functions:

- “Transmit torque from motor to wheels” (gearbox)

- “Sense pedal position” (accelerator sensor)

- “Provide corrosion resistance” (surface coating)

In PFMEA:

“The [Process] Function defines what the process step is supposed to accomplish.”

Examples of PFMEA functions:

- “Secure bolt with correct torque”

- “Assemble cover onto housing”

- “Apply adhesive uniformly”

2. Requirement: How Well the Function Should Be Performed #

A Requirement is the quantifiable or measurable criteria that define how well the function should be performed.

Key Points:

- Every function must have a measurable or verifiable requirement

- Requirements link to specifications, standards, or OEM expectations

Examples of requirement in FMEA:

| Function | Requirement |

|---|---|

| Transmit torque | 25 Nm ± 1.5 Nm |

| Seal housing | No leakage at 2 bar pressure for 10 minutes |

| Apply adhesive | Coverage area ≥ 90%, thickness 0.2–0.3 mm |

Without a requirement, there’s no way to define what failure means.

3. Failure: When the Function Does Not Meet the Requirement #

Failure is the non-fulfillment of a function or requirement. It is the central element of failure mode analysis.

In DFMEA:

“A failure is the inability of the design to meet its intended function or requirement.”

In PFMEA:

“A failure is the inability of the process to perform as intended (or within tolerance).”

Examples:

| Function | Requirement | Failure Mode |

|---|---|---|

| Transmit torque | 25 Nm ±1.5 Nm | Shaft slips under load |

| Provide sealing | No leakage under pressure | Fluid leak at gasket |

| Apply adhesive | 90% coverage | Adhesive skipped or misapplied |

The Logical Flow: Function → Requirement → Failure #

Visual Flow:

Function → Requirement → Failure Mode → Effect → Cause → Control → Action

This is how structured thinking works in FMEA. If this flow is incorrect or broken, your FMEA will be just a guesswork, not analysis.

Example from Automotive DFMEA: #

Item: Crankshaft Position Sensor

| Element | Description |

|---|---|

| Function | Detect engine crankshaft position |

| Requirement | Signal output: 0–5V, frequency range 30–200 Hz |

| Failure Mode | Signal dropout, no output, or wrong frequency |

This leads to:

- Effect: Engine misfire or no-start

- Cause: Sensor misalignment or electromagnetic interference

- Control: Sensor alignment gauge, shielding design

- Recommended Action: Add bracket support, improve connector seal

Example from Automotive PFMEA: #

Process Step: Torque bolt on seat frame

| Element | Description |

|---|---|

| Function | Fasten bolt with specified torque |

| Requirement | Torque = 48 Nm ± 2 Nm |

| Failure Mode | Under-torqued / Over-torqued / Bolt not tightened |

This leads to:

- Effect: Seat rattle or crash safety risk

- Cause: Operator skips torque step or tool malfunction

- Control: Automated torque tool with feedback

- Recommended Action: Add torque monitoring with visual OK/NOT OK indication

Summary Table #

| Element | Definition | Importance |

|---|---|---|

| Function | What the product/process is supposed to do | Starting point of analysis |

| Requirement | How well the function must be performed | Basis for evaluation |

| Failure | When the function doesn’t meet the requirement | Core of risk analysis |

Common Mistakes to Avoid #

- Listing incorrect functions like “Works properly”

- Always describe a measurable output under defined conditions

- Missing or generic requirements

- Include actual specifications (tolerance, pressure, voltage, time, etc.)

- Listing effects or causes as failure modes

- Failure = what happens when function doesn’t meet requirement

Yes. A single function may have multiple measurable parameters (e.g., torque, vibration, thermal resistance).

Yes. Without a requirement, you can’t define whether the function is fulfilled or failed.

Sometimes, yes — but always validate context. A leak in one case may be minor, in another it could be critical.