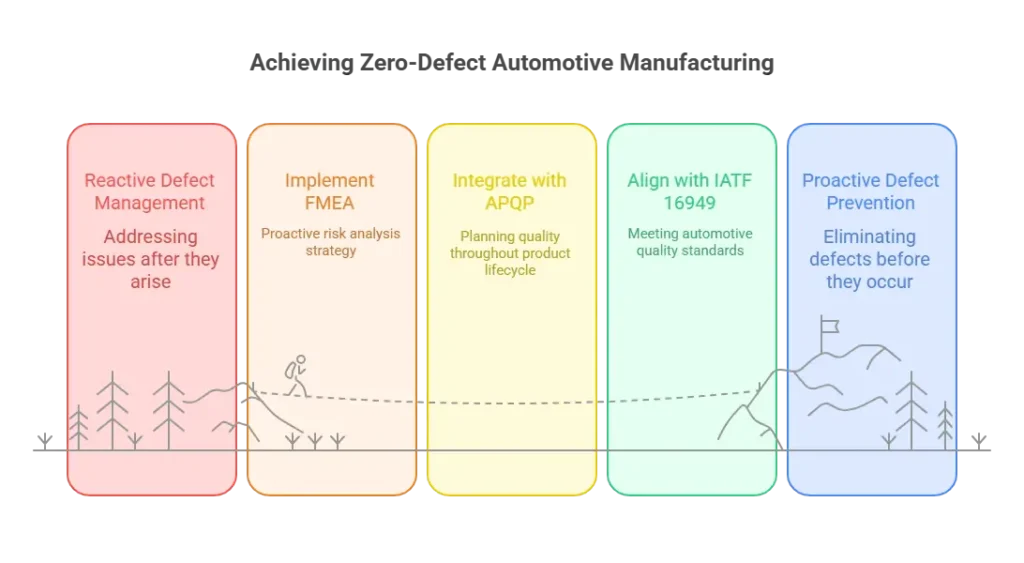

In the automotive industry, providing a product that is safe, reliable, and compliant is not optional, it is mandatory.

Therefore FMEA (Failure Mode and Effects Analysis) becomes important and it plays a key role in both below topics,

- APQP (Advanced Product Quality Planning)

- IATF 16949:2016 (Quality Management System Standard for Automotive Production)

FMEA is not just a documentation, it is a risk analysis strategy. Risk-based tool to ensure “do it right the first time” and achieve zero-defect manufacturing.

This article explains how FMEA fits into APQP phases and aligns with IATF 16949 requirements.

What is APQP? #

Advanced Product Quality Planning (APQP) is a structured method used by the automotive industry to ensure product quality is built into the design and manufacturing process from concept to production.

It is divided into 5 key phases:

- Planning and Definition

- Product Design and Development

- Process Design and Development

- Product and Process Validation

- Feedback, Assessment & Corrective Action

FMEA is one of the Core Tools used in multiple APQP phases.

Role of FMEA in APQP #

FMEA is integrated throughout APQP. It is not just as a single activity, but as a continuous input-output loop across 5 stages of APQP.

Phase-wise FMEA Application:

| APQP Phase | FMEA Activity |

|---|---|

| Phase 1 – Planning | Define scope, team, timeline for FMEA (5Ts) |

| Phase 2 – Product Design | Perform DFMEA to assess design risk |

| Phase 3 – Process Design | Develop PFMEA to address process risks |

| Phase 4 – Product and Process Validation | Confirm actions from DFMEA/PFMEA are implemented |

| Phase 5 – Feedback | Update FMEA based on lessons learned, field failures, etc. |

Tip: APQP requires evidence of effective use of FMEA during customer audits and PPAP submissions.

What is IATF 16949? #

IATF 16949:2016 is the global QMS standard created specially for the automotive industry.

It is based on ISO 9001:2015 but includes additional automotive-specific requirements, which including:

- Risk management

- Product safety

- Defect prevention

- Process capability

- Customer-specific requirements

IATF 16949 focuses on Risk-based thinking: FMEA is the primary method for risk analysis.

IATF mandatorily says that:

❝ Use of quality core tools including FMEA, Control Plan, MSA, SPC, and PPAP where applicable. ❞

(Ref: IATF 16949:2016, Section 8.3.5.1)

Role of FMEA in IATF 16949 Compliance #

FMEA directly supports and contributed to several IATF clauses:

| IATF Clause | FMEA Contribution |

|---|---|

| 6.1 – Actions to Address Risks | FMEA identifies, evaluates, and prioritizes risks |

| 8.3.5.1 – Design & Development Outputs | DFMEA ensures functional safety and robust design |

| 8.5.1.1 – Control of Production Processes | PFMEA drives Control Plan creation |

| 10.2.5 – Problem Solving | Lessons from FMEA feed into corrective actions |

| 9.1.1.1 – Monitoring & Measurement | PFMEA defines critical characteristics for SPC |

Not having FMEAs, or keeping them outdated, is a common major non-conformance in IATF audits.

Example: DFMEA & PFMEA Use in Real Project using APQP and IATF framework #

Scenario: Launching a Seat Position Sensor Module

| Stage | FMEA Used | Purpose |

|---|---|---|

| Design Development | DFMEA | Identify failure modes like signal drift, connector corrosion, housing crack |

| Process Design | PFMEA | Address risks like incorrect placement, soldering defect, incorrect calibration |

| Process Validation | FMEA Actions Verified | Confirm controls like vision system, torque tool poka-yoke, training effectiveness |

Each FMEA output is connected to Control Plan, Work Instructions, and PPAP Submission.

FMEA is a Living Document #

As per both APQP and IATF 16949:

- FMEA must be updated regularly

- Revisit after design changes, customer complaints, new failure data, or audit findings

- Must show evidence of risk reduction through recommended actions

FMEA acts as the bridge between design, process, and validation in the automotive quality journey.

Example – Linking FMEA to Standards #

Imagine a bolting process on an automotive assembly line:

- DFMEA Analyze the risk of product characteristics – Torque requirement.

- PFMEA identifies: Risk of under-torqued bolts – Effect = Component loosens in vehicle.

- Control Plan defines: Torque monitoring system + operator checks.

- PPAP submission shows: FMEA + Control Plan – proving risk prevention.

- IATF 16949 compliance: It all shows and demonstrate risk-based approach & customer requirement fulfillment.

Summary Table: FMEA in APQP & IATF #

| Feature | APQP | IATF 16949 |

| Purpose | Plan quality from the start | Manage and reduce risk |

| FMEA Type | DFMEA, PFMEA | Both mandatory |

| Document Status | Active during all phases | Must be current during audits |

| Linked Tools | Control Plan, DVP&R, PPAP | MSA, SPC, CAPA |

Yes. FMEA is a core tool required by IATF 16949 (ref: clause 8.3.5.1).

Excel is allowed, but many Tier-1s prefer APIS IQ RM, Plato SCIO, or Knowlence TDC for traceability and multi-user collaboration.

DFMEA and PFMEA are required documents in the PPAP package. Incomplete or outdated FMEAs may result in PPAP rejection.