An FMEA (Failure Modes and Effects Analysis) is strong only when created by the strong team in FMEA.

Why? Because risks exist in design, process, quality, maintenance, and customer use, no single person has expertise in all areas.

That’s why the AIAG-VDA 7-Step Approach tells us the formation of a cross-functional team (CFT) during Step 1 – Planning & Preparation.

When you form the right cross-functional team for FMEA, you ensure:

- Comprehensive risk identification

- Accurate evaluation of real-world failure causes

- More effective control strategies

- Greater ownership and buy-in for actions

That’s why the AIAG-VDA FMEA Handbook focus on team formation as an important activity in Step 1: Planning & Preparation.

What is a Cross-Functional FMEA Team? #

A cross-functional FMEA team is a group of stakeholders or persons from different departments and functions, they come together to perform a group risk analysis on a product or process.

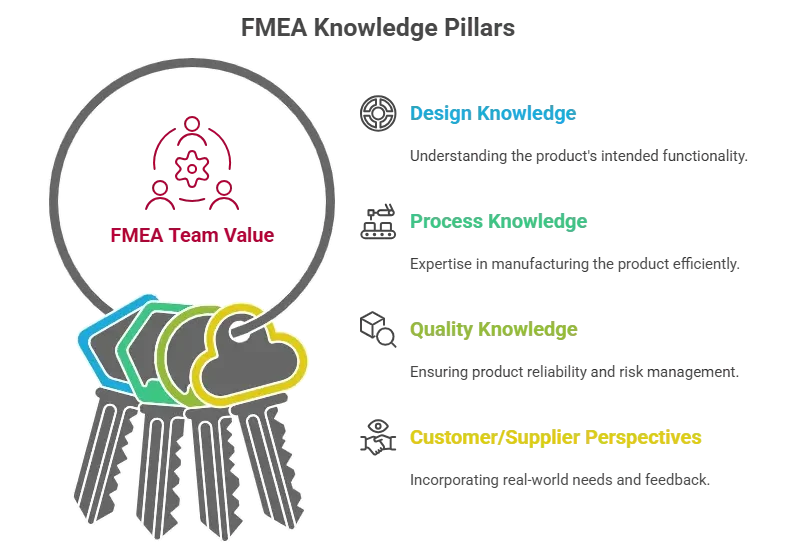

In FMEA, a CFT put their value in terms of:

- Design knowledge (how the product should work).

- Process knowledge (how the product will be made).

- Quality knowledge (how risks will be controlled).

- Customer/supplier perspectives (real-world requirements).

Each team member has a unique knowledge, which help to:

- Understand how the system or process is expected to function

- Find out potential issues based on their area of expertise

- Provide realistic preventive and detection controls

A good FMEA team reflects the entire lifecycle of the product or process from design concept phase to customer use.

Where Team Formation Fits in the 7-Step FMEA Process #

Team formation is part of Step 1: Planning & Preparation in the AIAG-VDA 7-Step FMEA approach.

FMEA Step 1 Activities:

- Define scope, boundaries, and assumptions

- Establish timeline and project milestones

- Assign roles and responsibilities

- Form a competent cross-functional team

- Apply the 5Ts (InTent, Timing, Team, Task, Tools)

Who Should Be in the FMEA Team? #

| Role | Area of Expertise | Typical Contribution |

|---|---|---|

| FMEA Moderator | FMEA methodology expert | He conduct meeting sessions and make sure the meetings are structured and efficient.Guides the team through AIAG-VDA methodology.Keeps focus on risk prevention, not just form-filling. |

| Product Engineer | Design Development expert | He is the responsible for Design FMEA. (Owner of DFMEA document)Identify design functions, failure modes, and design controls.Ensure all activities are align.Example: “If insulation material fails, motor overheats.” |

| Industrial Engineer | Process Development expert | He is the responsible for Process FMEA. (Owner of PFMEA document)Ensure all activities are align. |

| Design Engineer | Product design | Support on design features and specifications. |

| Process Engineer | Manufacturing knowledge | Identifies process risks and preventive strategies.Provides process flow, machine setup, and production knowledge.Identifies process-related risks.Example: “If torque wrench not calibrated, bolt may loosen.” |

| Quality Engineer | Standards, inspection | Ensures FMEA align with APQP, IATF 16949, and customer standards.Brings lessons learned from past projects, audits, and warranty data.Defines prevention and detection controls. |

| Manufacturing / Production Person | Operation know-how | Provides operator perspective.Shares real-world issues like human errors, machine downtime, environment conditions. |

| Supplier Quality | Purchased parts | Brings in supplier-related risk inputs about raw materials, purchased parts, and supplier risks. |

| Customer Representative (if applicable) | OEM expectations | Ensures customer-specific requirements are addressedShares expectations, critical requirements, and warranty issues. |

| Field/Service Engineer | Warranty and returns | Adds insights from customer failures and usage |

| Safety/Compliance Expert | Regulatory knowledge | Guides on safety-related severity and compliance issues |

Example: FMEA Team for Electric Power Steering (EPS) System #

| Team Member | Responsibility |

|---|---|

| FMEA Moderator / Facilitator | Facilitate AIAG-VDA DFMEA session |

| Design Lead | Define motor torque function, failure risks |

| Software Engineer | Analyze signal processing failures |

| Safety Engineer | Identify ISO 26262 impacts |

| Quality Engineer | Link DFMEA to Control Plan |

| Test Engineer | Provide validation data from DVP&R |

| Supplier Quality | Bring insights on sensor quality issues |

Example – DFMEA vs PFMEA vs FMEA MSR Team members #

| FMEA Type | Core Team Members |

|---|---|

| DFMEA | Design Engineer, FMEA Moderator, System Engineer, Quality Engineer, Safety/Compliance Expert |

| PFMEA | Process Engineer, FMEA Moderator, Manufacturing Engineer, Production Operator, Quality Engineer |

| FMEA-MSR | Systems Engineer, FMEA Moderator, Safety Engineer, Electronics Expert, Quality Engineer |

The FMEA Facilitator is common in all teams, he make sure a structured discussion and AIAG-VDA methodology are followed.

Common Mistakes in Team Formation (And How to Avoid Them) #

| Mistake | Solution |

|---|---|

| One-person FMEA | Always involve at least 3-5 stakeholders/persons |

| Missing key disciplines | Understand product lifecycle and involve experts |

| No FMEA moderator | Assign a trained facilitator for every session |

| Passive participation | Encourage active dialogue, clarify expectations |

| Late involvement | Include team early in design or process development |

Best Practices for Building Effective FMEA Teams #

- Limit core team size to 5-8 active contributors

- Schedule recurring FMEA sessions with set agendas

- Train all team members on AIAG-VDA methodology

- Use visual tools (boundary diagrams, function trees, etc.) to enhance clarity

- Link team to the scope – not every FMEA needs the same roles

- Rotate team members when moving from DFMEA to PFMEA

- Document team members in the FMEA record for traceability and audits

Sample FMEA Team Manager Template #

Use this table to record the team as part of FMEA documentation:

| Name | Department | Role in FMEA | Participation Date | |

|---|---|---|---|---|

| Ankit Sharma | Design | Define functions & requirements | ankit@abc.com | 01-Aug-2024 |

| Priya Mehta | Quality | Map controls & audit inputs | priya@abc.com | 01 – 20 Aug 2024 |

| Rajiv Nair | Manufacturing | Identify process risks | rajiv@abc.com | 03 – 25 Aug 2024 |

| Komal Verma | Moderator | Lead and document sessions | komal@abc.com | Full project |

Summary / Key learning #

- Cross-functional teams are essential for accurate and reliable FMEA results

- Involve members from design, process, quality, safety, and customer interfaces

- Form your team early during Step 1 of the AIAG-VDA FMEA process

- Assign a trained FMEA moderator to guide and document the sessions

- Keep records of participants for audit readiness and traceability

No. AIAG-VDA standard say that FMEA must be a team-based analysis to capture all functional and process-level risks.

o guide the team, apply correct methodology, resolve conflicts, and ensure documentation follows AIAG-VDA structure.

Ideally 5 to 8 active participants. Keep it small enough for efficient collaboration, but broad enough for complete analysis.

Not necessarily. Some members may overlap, but PFMEA typically includes more manufacturing and operations-focused roles.