Every powerful method has a story behind it, and the history of FMEA is no different. Failure Mode and Effects Analysis (FMEA) is now a standard tool in automotive manufacturing, but it’s not start there.

It starts from space industry, where people’s lives depended on predicting what could go wrong.

From NASA in the 1960s to AIAG’s industrial use, and now finally to the AIAG-VDA method, FMEA has evolved into one of the most important risk analysis tools in quality management.

Let’s dive into its journey.

FMEA Purpose at NASA: #

- Identify failure modes in spacecraft systems

- Analyze their effects

- Prevent mission-critical errors

This version of FMEA creates the foundation for systematic risk analysis, no more wait for failure, but early identification.

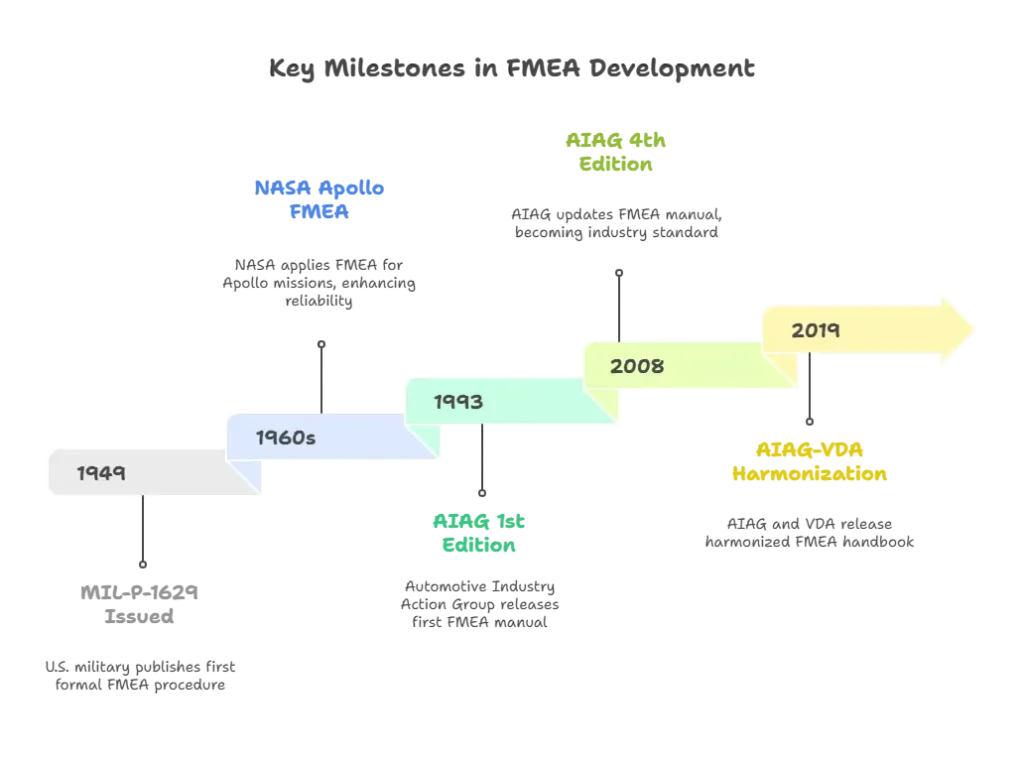

Note: The earliest official reference is MIL-P-1629 (U.S. Military Procedure), issued in 1949 and updated in the 1960s for aerospace programs.

1970s–1980s – Adoption in Industrial & Automotive Sectors #

After its success in aerospace, FMEA use cases applied into nuclear energy, medical devices, and automotive manufacturing.

The automotive sector saw the FMEA potential to prevent issues during design and production, reduce warranty costs, and improve customer satisfaction.

1993 – AIAG Releases First FMEA Manual #

The Automotive Industry Action Group (AIAG) published its first FMEA manual in 1993 in alignment of U.S. automotive suppliers (Ford, GM, Chrysler) on a common approach to follow this risk analysis tool.

AIAG Focus:

- Separate DFMEA (Design) and PFMEA (Process) structures

- Risk evaluated using Severity × Occurrence × Detection [RPN (Risk Priority Number)]

Over the years, the AIAG FMEA manual go through several modifications and updates:

- 2nd Edition (1995)

- 3rd Edition (2001)

- 4th Edition (2008) – Most widely used before latest harmonization of AIAG-VDA.

RPN had limitations, teams regularly ignored high severity issues with good detection scores. This lack of scoring needs a more refined evaluation system.

Parallel Development – VDA’s Approach in Germany #

In parallel to AIAG, German automakers developed their own FMEA method under the VDA (Verband der Automobilindustrie) association.

VDA’s approach focuses on:

- Structured templates

- Robust documentation

- Greater focus on functional safety (ISO 26262)

After this action two different FMEA methodologies are being followed, Which is creating confusion for global suppliers.

2019 – AIAG-VDA Harmonized FMEA Handbook #

Automotive suppliers need to follow two methodologies for American OEMs and German OEMs. Therefore, to eliminate and disconnect between American and German OEMs, AIAG and VDA jointly released the AIAG-VDA FMEA Handbook in June 2019.

This harmonized method brought both worlds together and made a global standard for FMEA.

Key Highlights of AIAG-VDA FMEA:

| Old AIAG (4th Ed.) | AIAG-VDA (2019) |

| 5-step process | 7-step structured approach |

| RPN (S×O×D) | Action Priority (AP) tables |

| Vague planning | Emphasis on boundary/scoping (5T questions) |

| Limited linkage | Stronger linkage to Control Plan & Lessons Learned |

This standard is now required by several OEMs (VW, Ford, GM, Stellantis, BMW, Mercedes, etc.) and aligns well with APQP, IATF 16949, and functional safety ISO 26262.

Timeline Summary: FMEA Evolution #

| Year | Milestone |

| 1949 | MIL-P-1629 issued (U.S. military procedure) |

| 1960s | NASA applies FMEA during Apollo missions |

| 1970s–80s | Industrial adoption (automotive, nuclear, medical) |

| 1993 | AIAG releases 1st edition FMEA manual |

| 2008 | AIAG 4th edition becomes industry standard |

| 2019 | AIAG-VDA harmonized FMEA handbook released |

Why This Evolution Matters for You #

As a quality engineer or FMEA moderator, understanding FMEA’s evolution helps you:

- Communicate its importance to cross-functional teams

- Justify the need for upfront preventive planning

- Apply the latest AIAG-VDA 7-step method correctly

- Meet the expectations of global OEMs and Tier-1s

Conclusion #

The journey of FMEA from space to automotive to many industries now, proves one thing:

Prevention is always better than correction.

What started as a mission-critical tool at NASA is now a core pillar of quality management in the automotive world.

Make sure you’re using the latest methodology (AIAG-VDA) to stay compliant with industry best practices.

It is required by several OEMs like VW, Mercedes, BMW, Ford, GM, and Stellantis. Suppliers are expected to follow the harmonized format.

Some suppliers may still accept it, but the AIAG-VDA method is considered the new industry best practice. Take approval from customers before continuing to the old AIAG 4th edition FMEA.

The AIAG method focused on RPN, while VDA followed action priority documentation and structured risk reduction. The AIAG-VDA method combines the methodically best tool.